Name:PTFE Tape

Place of Origin:Jiangsu ,China

Material:PTFE Film

Adhesive Type:Pressure Sensitive

Width:10/15/19/25/50mm/etc.

Length:10m

Thickness:0.08/0.13/0.18/0.25mm etc.

Pure PTFE Film Tape Description

Pure PTFE (Polytetrafluoroethylene) Film Tape is a premium-grade material engineered for extreme reliability across industrial, electrical, and mechanical applications. Backed by a skived PTFE film and often coated with a pressure-sensitive silicone adhesive, it delivers unparalleled performance in demanding environments.

Name | PTFE Tape | Place of Origin | Jiangsu ,China |

Brand | Ekingtech | Design Printing | No printing |

Material | PTFE Film | Adhesive | Silicone |

Adhesive Side | single sided

| Adhesive Type | pressure sensitive |

Width | 10/15/19/25/50mm/etc. | Length | 10m |

Thickness | 0.08/0.13/0.18/0.25/etc. | Temperature resistance | -70℃~+300℃ |

Feature | Heat-resistant | ||

Application | Masking | ||

Packing | plastic bag + carton or customized | ||

-Exceptional Temperature Resistance

Withstands temperatures from -70℃~+300℃, maintaining integrity in both cryogenic and high-heat settings like industrial ovens or aerospace component.

-Unmatched Chemical Inertness

Resists virtually all chemicals—including acids, alkalis, solvents, and even aqua regia—making it ideal for corrosive environments in chemical processing or pharmaceutical equipment.

-Ultra-Low Friction & Non-Stick Properties

Boasts the lowest coefficient of friction among solids, reducing mechanical wear and noise while ensuring effortless release of adhesives, resins, or contaminants without residue

-Superior Electrical Insulation

Provides high dielectric strength and stability, essential for transformers, wire harnesses, and high-frequency cables.

-Durability and Versatility

Waterproof, non-aging, and resistant to UV/weathering, it excels in applications from pipe-thread sealing and conveyor systems to food-safe machinery and medical devices

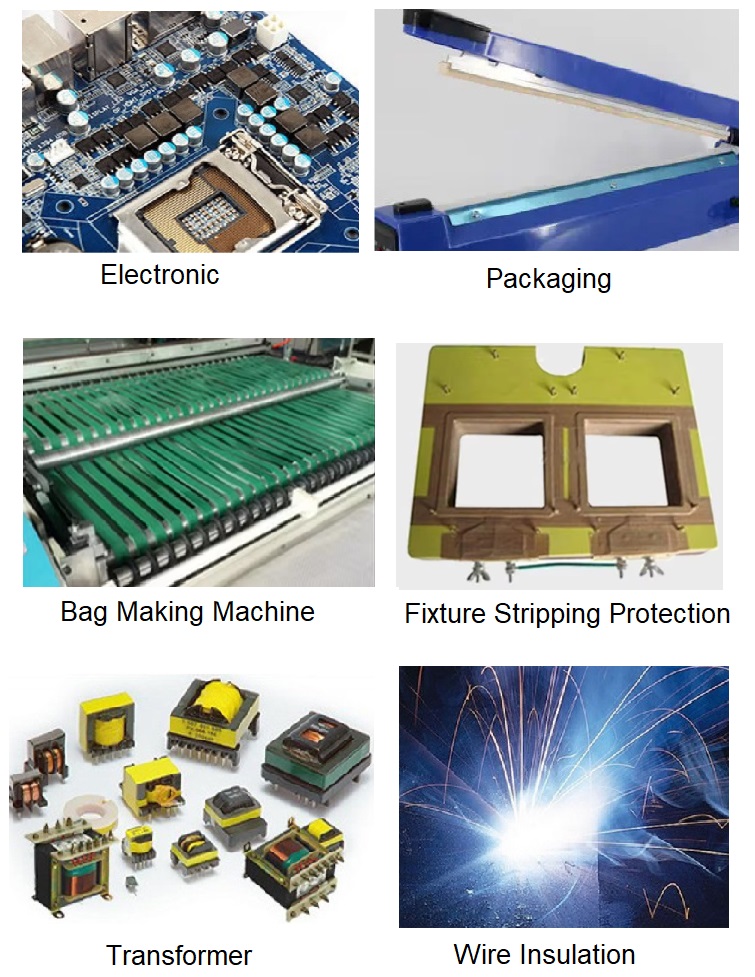

Application

-Packaging: Heat-sealer jaw protection in food/pharmaceutical packaging.

-Industrial Processes: Release surfaces for composite molding, plastic extrusion guides.

-Electrical Engineering: Insulation layer for wire harnesses, transformer coils.

-Printing/Laminating: Non-stick rollers in hot-melt adhesive systems.

-Laboratory Equipment: Protective covers for heated platens and sensitive instruments.

.......

We chat