In high-demand industrial application, choosing the correct tape is not just about cost, but

about performance & safety. Polyimide Tape & PET tape both are high-performance tape

offering excellent performance. understanding the technical differences will guide you

purchasing decision and reduce product failure risk.

They are film-based adhesive tapes widely used in demanding industrial environments.

The key difference is film which leads their thermal limits and specific applications.

1.Polyimide Tape VS PET tape

(1)Thermal Performance: they are both high-temperature tape

-Polyimide Tape uses polyimide film backing which is exceptional thermal stability. It is

the extreme heat specialist excels in extreme heat.

Widely used in electronics manufacturing (e.g., PCB soldering, insulation), aerospace

components, extreme temperature masking.

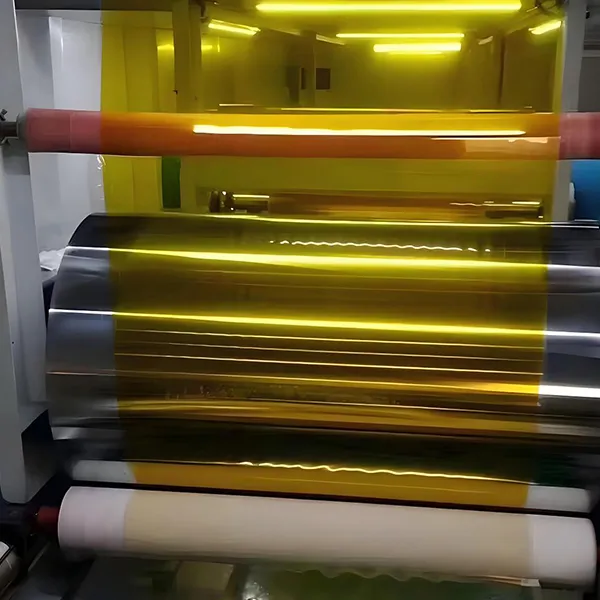

-PET Tape use polyester film backing. It offers a strong balance of properties with more

accessible price .It performs very well in general high-temperature application, but

not at the extreme levels of polyimide.Eg. paint baking or general electrical insulation .

(2)Electrical Insulation

-Polyimide Tape: Superior dielectric strength, preferred for very sensitive electronic.

-PET Tape: Excellent dielectric strength for general electrical insulation. Applied in coils,

transformers, and capacitors.

(3)Mechanical Strength & Durability

In some application, PET Tape is more rigid than Polyimide Tape offering good tear resistance.

(4)Chemical Resistance

-Polyimide Tape is excellent resistance to most chemical, oil, and solvent, crucial for chemical

processing or electronics cleaning.

-PET Tape is good resistance to common chemicals, but generally less robust than polyimide

in highly aggressive chemical environments.

(5)Cost Effective

Polyimide tape is higher cost than pet tape

2.When Is Prioritize Polyimide Tape

(1)Extreme Thermal Load

It is applied wave soldering, reflow ovens, or continuous exposure to temperatures above 150°C.

(2)Critical Electrical Insulation

It is for sensitive electronic components

(3)Precision Masking

Applied in residue-free removal after exposure to very high temperatures, like polyimide masking

tape for gold fingers.

(4)Aerospace. It is aerospace adhesive tape.

3.When Is Prioritize PET Tape

(1)General High-Temperature Masking

For processes of temperature below 170°C, eg. automotive paint baking.

(2)Standard Electrical Insulation

General-purpose insulation in transformers, motors, and wire harnessing where extreme heat isn't sustained.

(3)Splicing & Holding

For general industrial bonding, bundling, or splicing.

(4)Cost-Effectiveness

For more budget-friendly price with high-volume application.

4.Summary

| Property | Polyimide Tape | PET Tape |

|---|---|---|

| Temperature Resistance | Up to 260°C | Up to 150°C |

| Chemical Resistance | Excellent | Moderate |

| UV Resistance | Very High | High |

| Electrical Insulation | Superior | Moderate |

| Application | Electronics, Aerospace, Batteries | Masking, Packing, Labeling |

| Cost | Higher | More Economical |

| Application | PCB masking (soldering), High-temp electrical insulation, Aerospace, 3D printing heat beds | General masking, Electrical insulation (motors, transformers), Splicing, Packaging, Surface Protection, Light duty powder coating |

Understanding the different of Polyimide Tape and PET Tape, you can choose corrrect tape to meet

your application demand, optimizing performance and controlling costs.

Contact our specialists today for a tailored quote with custom adhesive tape solution.

Website: www.ekingindustrialtape.com

We chat