In industrial sectors, Purchasing right teflon tape is very important. It's not just buying PTFE tape,

but investing in a critical component which impacts production efficiency & product quality.This

guide navigates you different type of PTFE tape & industrial application, and how to choose a

reliable PTFE tape supplier.

PTFE tape is also called Teflon tape, which is a high-performance adhesive tape well knowed for its

exceptional non-stick property, heat resistance, and chemical inertness. Its unique characteristics

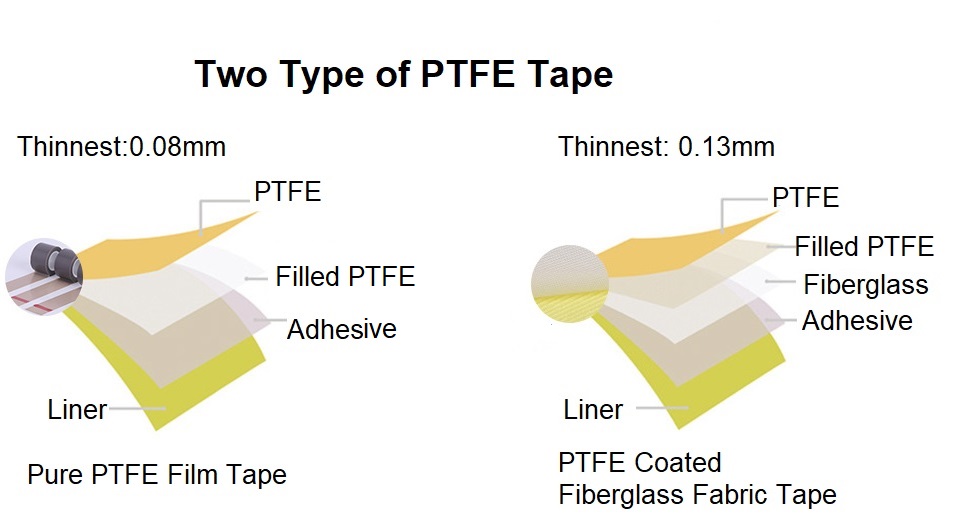

make it indispensable in demanding industrial. There is two main types .

PTFE Coated Fiberglass Fabric Tape

It's constructed by fiberglass fabric with PTFE resin & high-temperature silicone adhesive.

-Fiberglass Fabric provides high tensile strength, excellent dimensional stability & tear resistance.

-PTFE Resin Coating has the characteristic of non-stick, low-friction, and chemical-resistant surface.

-Silicone Adhesive Layer offers strong adhesion at high temperatures & clean removal.

-Release Liner protects the adhesive before application.

1.Advantage

-Strong mechanical durability

-Resistant to heavy wear and friction

-Withstands repeated high-heat cycles

2.Main application

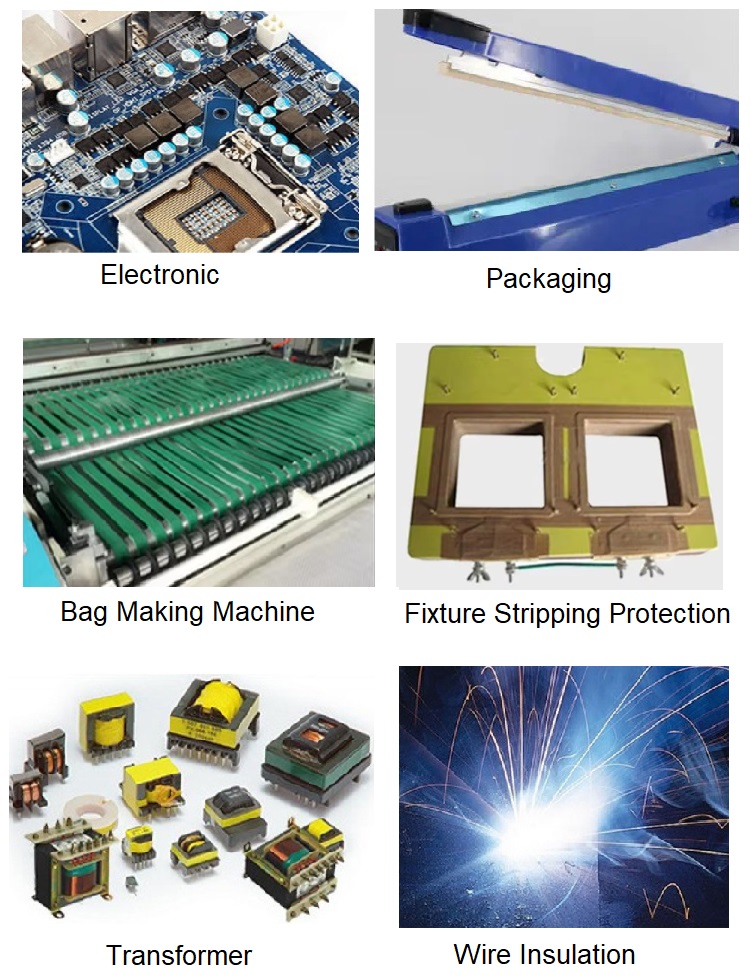

-Heat Sealing: Ideal for packaging machinery because of its durability & non-stick surface.

-Baking & Drying: Used as non-stick conveyor belt or liner in industrial oven, dryer & food

processing line.

-Textile & Printing: Applied on heat press platens, dryer drums, release liners in screen printing.

-Composite Molding

-General Industrial Release

Pure PTFE Film Tape

It's made from pure PTFE with silicone or acrylic adhesive.

-Pure PTFE Film Provides exceptional dielectric strength /electrical insulation/, ultra-low friction,

and supreme chemical inertness.

-Silicone or Acrylic Adhesive Layer:Silicone is high-temp, acrylic is strong initial tack and good

aging.

-Release Liner protects the adhesive.

1.Advantage

-Superior Electrical Insulation.

-Ultra-low friction

-High Chemical Inertness

-High Conformability & Flexibility

-Lower Tensile Strength

2.Application

-Electrical Insulation: Wrapping coils, capacitors, transformers &sensitive electronic components.

-Low Friction/Sliding Surfaces: Used as liners for chutes, guide rails, or bearings .

-Chemical Processing: Sealing, gasketing, or lining surfaces.

-Wire & Cable Wrapping

-Precision Masking

Comparison:PTFE Coated Fiberglass Fabric Tape vs. Pure PTFE Film Tape

Our factory can offer you

-Uncompromising Quality: Strict 7-step QC processes, adherence to international standards like SGS,

RoHS, REACH.

-Precision Manufacturing:Slitting and rewinding with ±0.1mm accuracy which ensure the tape fits your

machinery perfectly.

-Flexible Customization: offer tailored solutions for specific sizes, colors, liners, or unique performance

requirements.

-Fast lead times :2-3 days for samples, 5-10 working days for mass production.

Contact us for a free consultation, Let's discuss your specific application needs and help you improve

your roduction efficiency & product quality. Pls visit our website: www.ekingindustrialtape.com

We chat