As industrial bonding solution developing, acrylic tape is leading the charge. This article explores why

industrial acrylic tape is Replacing mechanical fasteners like screws and rivets.

Why Acrylic Tape is the Future of Fastening

-High Efficiency& Cost Saving. Screws require drilling and alignment, acrylic bonding tape dont need

drilling, grinding, clean-up , which significantly reduces labor &slashing assembly time.

-Versatility. No matter automotive acrylic tape or transparent acrylic tape,they bond different materials

from metal, glass , plastic,composites to painted surfaces

-Superior Durability & Reliability. Acrylic adhesive tape is excellent resistance to UV light, chemical &

moisture, which ensures long-term performance in different environments.

-Solving Industry Pain Points.

Screws rust, loosen & damage surfaces. Acrylic adhesive tape is invisible bonds with ultra-strong ,

long-lasting bonding,light weight.

-Vibration Damping & Noise Reduction. Acrylic Foam Tape absorbs vibration and noise, improving driving

comfort experience.

Comparing Acrylic Tape with Mechanical Fastener

Bonding Method | Speed | Durability | Cost | Versatility |

Acrylic Tape | High (seconds to apply) | Excellent (UV, heat, moisture resistant) | Low | High (bonds multiple surfaces) |

Mechanical Fastener | Low (requires tools, drilling) | Good (but prone to rust) | High | Moderate |

Diverse Applications

Industrial acrylic tape is transforming industries worldwide. It delivers strong, clean bonds,leading it a priority

choice for distributors and procurement professionals. Here is main applications.

-Automotive Industry

Automotive acrylic tape(eg VHB tape) is widely used for attaching trim, emblems, and panels. It’s ideal for

exterior and interior applications because of vibration resistance & weatherproofing .

-Electronics Manufacturing

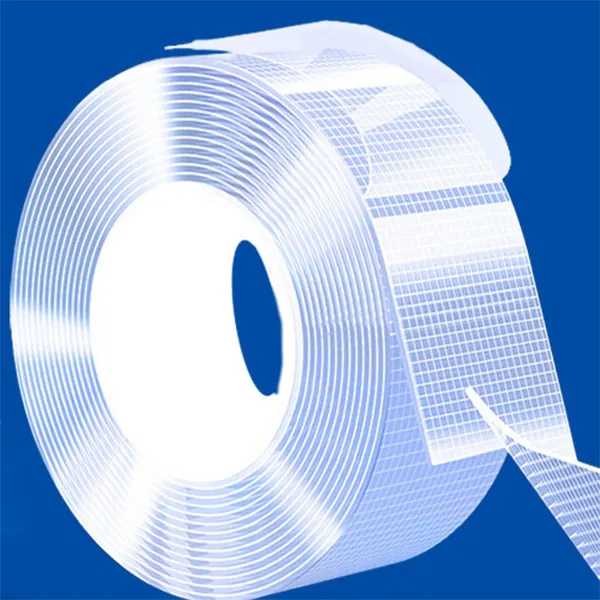

Transparent acrylic tape & double-sided acrylic tape offer precision bonding in delicate components such as

touchscreens & circuit boards.

-Construction and Signage

Acrylic foam tape is superior adhesion for outdoor settings such as mounting signs, cladding, and architectural

panels with UV resistance and weatherproofing .

Here’s a quick overview of three type of acrylic tapes which are vapplied in multitude industries.

Tape Type | Thickness | Key Feature | Main Application |

Acrylic Foam Tape (eg VHB Tape) | 0.5 - 3.0 mm | ultra-strong & long-lasting bonding, absorbs vibration and noise, weather & UV resistant, replace mechanical fasteners | Automotive Building & Construction (curtain walls, panels), Electronics (structural) |

Double Sided Acrylic Tape | 0.05 - 0.3 mm | strong adhesion, UV resistance, versatile use, easy to die-cut | Electronics (display mounting, battery fixing), Appliances (panels, badges), Signs & Displays, General Assembly |

Transparent Acrylic Tape | 0.05- 0.2mm | clear, invisible bond, high initial tack, excellent die-cut ability | Optical Components, Touchscreens, Lens Mounting, Display Assembly, Thin Film Lamination |

Industrial acrylic tape is not just a trend,but a strategic move towards more efficient, durable, pleasure experience .

Ekingtech as a acrylic adhesive tape supplier, provide to custom acrylic tape solution. Whether you're a wholesaler,distributor or OEM we’re ready to deliver.

✅ Request Samples

✅ Get a Free Quote

✅ Discuss Custom Specs for OEM

Visit our website: www.ekingindustrialtape.com or

Email us: info@ekingindustrialtape.com

We chat