Name:Anti-static PTFE Tape

Place of Origin:Jiangsu ,China

Material: PTFE

Adhesive Type:Pressure Sensitive

Width:10/15/19/25/50mm etc.

Length:10/30/50m etc

Thickness:0.08/0.13/0.18/0.25mm etc.

Working Temperature:-70°C to 350°C

Anti-static PTFE tape integrates conductive fillers (e.g., carbon black) into PTFE-coated glass fiber fabric, enabling surface resistivity of 10⁶–10⁹ Ω to prevent electrostatic discharge (ESD) in sensitive electronics.

Key Advantages:

-Static Dissipation: Surface resistivity maintained at 10⁶–10⁸ Ω

-Extreme Temperature Resistance: Continuous service up to 260°C (short-term: 300°C)

-Non-Adhesive Surface: Low friction coefficient (0.05–0.1) prevents residue buildup

-Chemical Immunity: Resists acids, alkalis (e.g., aqua regia), and solvents

-Durability: Glass fiber reinforcement enables high tensile strength (≥1,700 N/100mm) and abrasion resistance

⚡ Critical Value: Unifies ESD safety, thermal stability, and chemical resilience—essential for precision industries where contamination or static discharge risks are unacceptable.

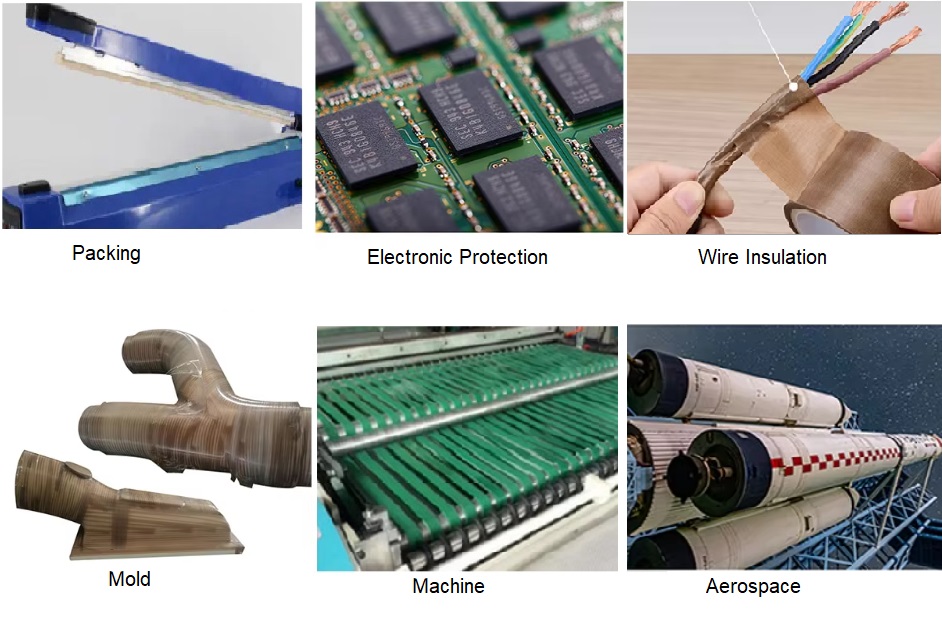

Application

-Electronics Manufacturing: Protects ESD-sensitive components in semiconductor equipment, PCB assembly, and LCD production

-High-Temperature Industrial Processes: Used on rollers for packaging heat sealers, plastic extrusion guides, and textile drying drums

-Explosive/Hazardous Environments: Prevents static sparks in chemical plants and fuel-handling systems

-Food & Pharmaceutical Packaging: FDA-compliant variants ensure static-free heat sealing

We chat