As industrial development, PET tape for electronics and automotives become a reliable choice for

demanding environment .with excellent resistance to heat, chemical & mechanical stress, it ensures

good performance in precision assembly.This article explores themain advantages of PET tape for

international B2B buyer & engineer.

1.The Essential Layer of PET tape

PET tape is called Polyester tape, which is made from pet film coated with acrylic or silicone adhesive.

The Essential Layers are PET film backing and adhesive layer.

(1) PET Film Backing: it is backbone of the tape, delivers key important features.

-Superior Tensile Strength:With stand tearing and stretching ,last long time in mechanical environment.

-Excellent Dimensional Stability:PET film also has good stability for complex tasks such as component

masking or accurate splicing.

-Preferred Electrical Insulation : its high dielectric strength is indispensable for safeguarding electrical

components and ensuring

operational safety in circuits.

(2)Adhesive Layer: The type of adhesive coating highly influence PET tape performance. There are two

types .

-Acrylic Adhesive: it is commonly used pressure-sensitive adhesive (PSA) which is reliable initial tack,

outstanding aging resistance,excellent weatherability, and strong bonding across diverse substrates. Acrylic-based PET tapes typically perform well in continuous temperatures -20~120°C.

-Silicone Adhesive: This PSA is specifically for its unrivalled high-temperature resistance, often with

standing up to 200°C or more in short time. It is applied in precision masking because of its residue-free

removal

2.Eco-friendly PET tape is widely used in electronics and automotive manufacturing.

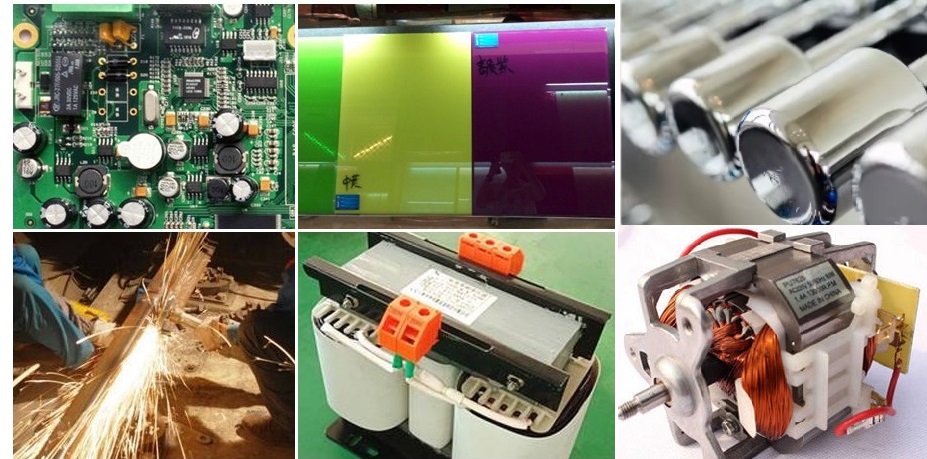

(1) PET Tape for Electronics :Precision,Protection

-PCB masking:high temperature PET tape is used in wave soldering and reflow soldering,the color is

usually green and blue.Use in masking gold fingers and sensitive components of Printed PCB.

-Electric Insulation: Widely used for electrical insulation to securing windings in transformers,inductors

and small motors. High dielectric insulation substantially reduces the risk of short circuits

-Component Holding:Offer secure, temporary,vibration dampening, or permanent fixing of discrete

components like capacitors or resistors onto circuit boards or within enclosures.

-Battery Pack Assembly:Insulating and Taping of Individual Batteries and Battery Packs.Enhancing safety

and thermal management within portable electronics and EVs.

(2)PET Tape Automotive: Exceptional Reliability and Performance

-High-Temp Paint Masking: Ideal for masking windows,door jambs and other surfaces for high-temp baking

cycles at automotive paint shop. It resists temperatures up to 200°C without melting or leaving an adhesive residue for a top-quality finish.

-Wire Harnessing: PET tape for wire harnessing is suitable for wire harnesses wrapped within the

throughout vehicle,from the engine room to the passenger cabin. It offers stable adhesion ,heat resistant, insulation and protection .

-Temporary Component Holding: Used during assembly processes to temporarily hold components, trims,

or cables in place before final fixing, ensuring efficient line operations.

-Surface Protection: Applies as a temporary protective layer on painted surfaces or sensitive components

during transit or assembly to prevent scratches, chips, or minor impacts.

3.Summary

Feature | Description | Application |

High-Temperature Resistance | Withstands elevated temperatures during processing, curing, or operation. | -Electronics: PCB masking during soldering, oven curing. -Automotive: High-temperature masking for painting/powder coating, engine bay wiring. |

Excellent Electrical Insulation | Prevents electrical current flow, safeguarding components and circuits. | -Electronics: Coil wrapping, transformer insulation, battery pack insulation. -Automotive: Wire harness insulation, sensor protection. |

Superior Adhesion & Clean Removal | Forms a strong bond, yet removes cleanly without leaving residue (especially silicone adhesive). | -Electronics: Temporary holding of delicate components during assembly. -Automotive: Precision masking for two-tone painting, temporary surface protection. |

High Tensile Strength & Durability | Resists tearing, stretching, and abrasion, offering robust mechanical protection. | -Electronics: Component bundling, protective wrapping. -Automotive: PET tape for wire harnessing, abrasion protection on surfaces. |

Dimensional Stability | Maintains shape and size consistently, even under varying conditions. | -Electronics: Precise masking in intricate circuit designs. -Automotive: Ensuring accurate mask lines during painting processes. |

Chemical Resistance | Resists degradation from oils, solvents, and cleaning agents. | -Electronics: Protection during chemical cleaning steps. -Automotive: Used in environments exposed to vehicle fluids and lubricants. |

Our factory custom PET tape and wholesale PET tape tailored for your market,With certified quality,customizing flexibility and fast lead time.

If you are a importer,OEM purchaser, we support you success in both PET tape for electronics and PET tape automotive markets.

Request a free PET tape sample or get a tailored quote for wholesale PET tape.

Email: info@ekingindustrialtape.com

or visit: www.ekingindustrialtape.com

We chat