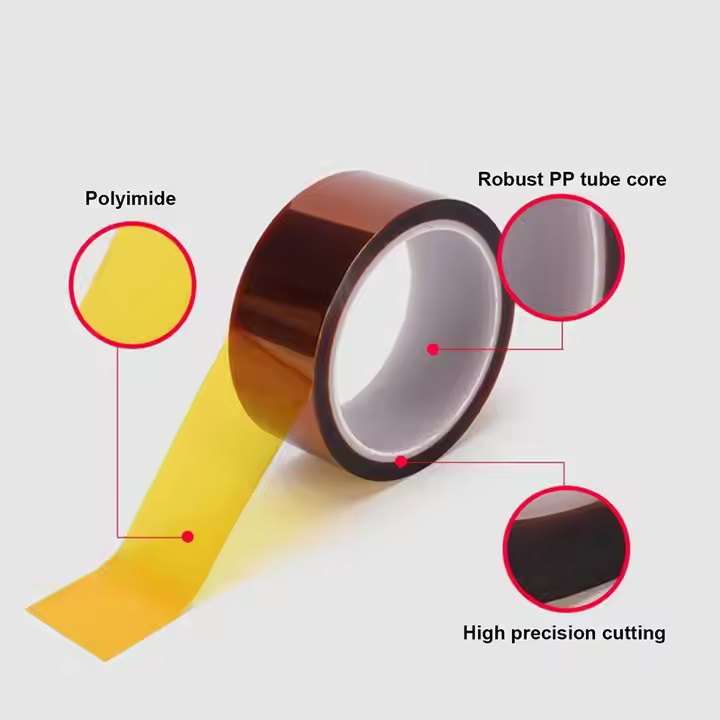

Name: Single Sided Polyimide Tape

Place of Origin:Jiangsu ,China

Material:Polyimide Film

Adhesive Type:Silicone

Adhesive Side:Single Sided

Width:10/15/20/50mm etc.

Length:33/50/66m etc

Thickness:0.05/0.06/0.08mm/0.10mm etc.

Single Sided Polyimide Tape is a high-performance adhesive tape made from a durable polyimide film coated with a heat-resistant silicone adhesive on one side. It's widely recognized for its distinctive amber color and exceptional properties in extreme conditions. This tape provides reliable insulation and protection in applications exposed to high temperatures and harsh chemicals.

Feature of Single Sided Polyimide Tape

Exceptional High Temperature Resistance: It can withstand continuous temperatures typically up to 260°C (500°F) and even higher for short periods, making it ideal for thermal processes.

Clean Removal: The silicone adhesive ensures it peels off cleanly after use, leaving no residue, which is crucial for sensitive electronic components.

Superior Electrical Insulation: It provides excellent dielectric strength, effectively insulating electrical components and preventing short circuits.

Chemical and Solvent Resistance: The polyimide film and silicone adhesive are highly resistant to various chemicals, oils, and solvents, ensuring durability in harsh environments.

High Mechanical Strength: It offers good tensile strength and abrasion resistance, providing robust protection.

Thin and Flexible: Ultra-thin design allows for precise application in confined spaces.

High Adhesion: Offers strong bonding to various surfaces with minimal residue upon removal.

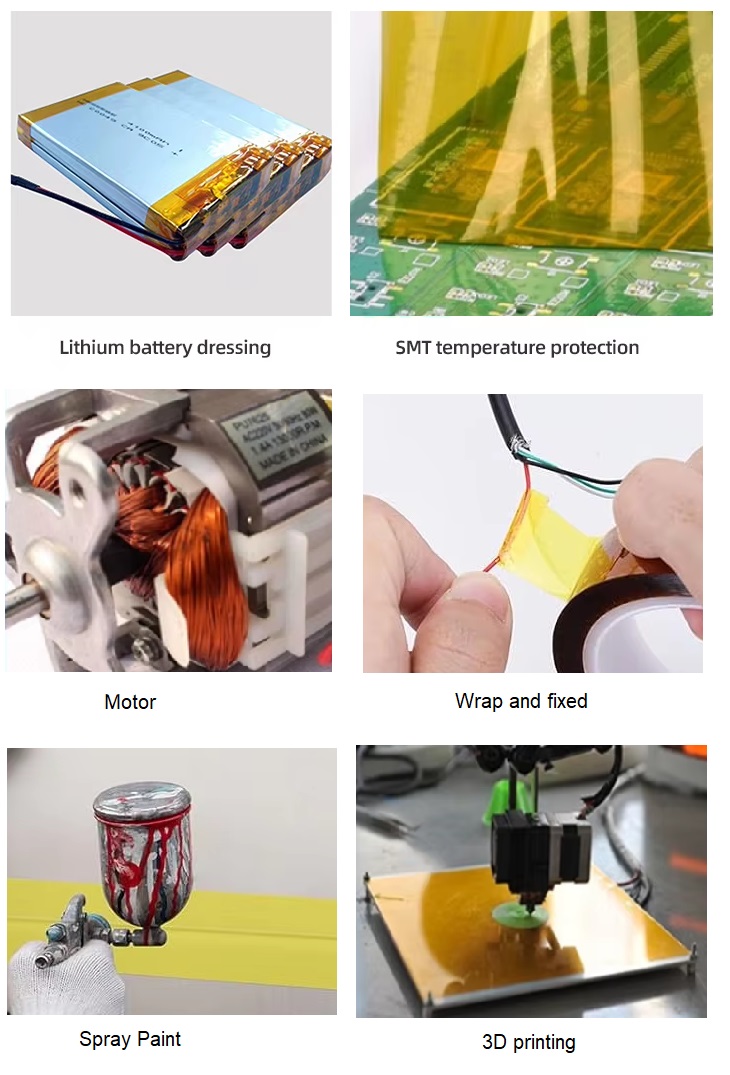

Application of Single Sided Polyimide Tape

Electronic Component Mounting: Ideal for securely attaching heat sinks to processors, bonding flexible printed circuits (FPCs) to rigid boards, or affixing other electronic components.

lithium battery manufacturing for securing and insulating battery components

High-Temperature Masking: Utilized in powder coating, e-coating, and other high-temperature painting or coating processes to protect areas that should remain uncoated.

Sensor and Module Integration: Perfect for permanent attachment of various sensors or small modules in automotive, aerospace, and consumer electronics.

High-Temperature Lamination: Applied in processes requiring the lamination of different materials that must withstand elevated temperatures.

aerospace and automotive industries for bonding parts in high-heat environments.

medical devices and optical equipment for precision bonding and insulation.

3D printing and powder coating for surface protection and heat resistance.

We chat